Pharmaceutical Microbiology and its importance

Anup Bajracharya

Microbiology

is the scientific study of microorganisms such as bacteria, archaea, algae,

fungi, protozoa, viruses, and certain helminths. This field focuses on

understanding their structure, functions, classification, and the methods used

to either utilize or regulate their behavior. When the principles, methods, and

knowledge of microbiology are specifically applied to pharmaceutical processes,

it becomes known as Pharmaceutical microbiology.

Pharmaceutical Microbiology is the applied science concerned

with the study of microorganisms that are involved in:

- the

production of pharmaceutical products,

- ensuring

their safety,

- maintaining

their quality and sterility,

- and

preventing microbial contamination during drug development and production.

Pharmaceutical Microbiology can

be defined as the study of microorganisms that are pertinent to the production

of antibiotics, enzymes, vitamins, vaccines, and other pharmaceutical products;

it also incorporates the study of microorganisms that cause pharmaceutical

contaminations, and degradation, deterioration and spoil of pharmaceutical raw

materials and finished products.

Importance

of Pharmaceutical Microbiology

Pharmaceutical Microbiology

is a vital discipline that plays a key

role in ensuring the safety, quality, and effectiveness of pharmaceutical

products. It is essential across every stage of drug development and

production.

1.

Production of Antibiotics, Vaccines, enzymes etc

Microorganisms are used in the

development and production of antibiotics vaccines, enzymes, monoclonal

antibodies, etc. It ensures biosafety and purity of these biological products.

· Production of antibiotics- The most important use is the

production of antibiotics, two third of antibiotics are produced from

microorganisms. The pharmaceutical microbiology concerns with the isolation of

antibiotic producing microorganisms from natural environments such as soil or

water and use them for production of antibiotics through the process of

fermentation. Thus, Microbiology helps in strain selection, fermentation

monitoring, and antibiotic

potency testing.

Production of vaccines- A vaccine is a biological preparation that

improves immunity to a particular disease. A vaccine typically contains an

agent that resembles a disease-causing microorganism, and is often made from

weakened or killed forms of the microbe, its toxins or one of its surface

proteins. The agent stimulates the body's immune system to recognize the agent

as foreign, destroy it, and "remember" it, so that the immune system can

more easily recognize and destroy any of these microorganisms that it later

encounters.

Vaccines

are often made from killed or weakened (attenuated) microorganisms, or specific

components like proteins or toxins. Pharmaceutical microbiologists help to

- Select

the right strain of bacteria or virus.

- Grow

them in optimal culture media under controlled conditions (e.g.,

temperature, pH, aeration). Example: Using Salmonella typhi Ty21a strain

for oral typhoid vaccine production.

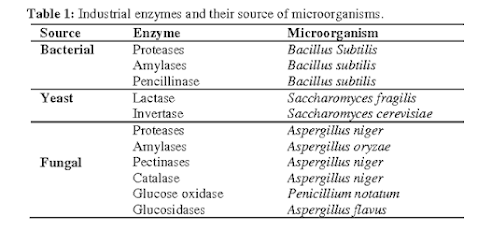

· Production of Enzymes-Microbial cells also produce intracellular

and extracellular enzymes like amylase, proteases, lipases, invertase etc. Enzymes

are collected either from the culture

medium (extracellular enzymes) or from microbial cells (intracellular enzymes).

Examples- Amylase, protease, and lipase:

Included in digestive formulations for patients with poor digestion. Streptokinase and urokinase helps to dssolve blood clots

(used in heart attack treatment).Glucose

oxidase is used in glucose biosensors for diabetics. DNA polymerases from Thermus

aquaticus (Taq polymerase) is essential in PCR (Polymerase Chain Reaction) for genetic testing and disease

diagnosis.

· Production of Alcoholic products- Many microbial cells convert raw

materials or substrates into valuable organic compounds such as butanol, ethanol,

acetone etc. The production of alcoholic beverages and products is achieved

through fermentation, a

metabolic process in which microorganisms—mainly yeasts and bacteria—convert sugars into alcohol (ethanol) and other byproducts like carbon

dioxide.

· Production of Probiotics – Probiotics are live bacteria that may

confer a health benefit on the host. Fuller in 1989 described probiotics as

"live microbial feed supplement which beneficially affects the host animal

by improving its intestinal microbial balance

Lactic acid bacteria (LAB) and Bifidobacteria are the most common types of

microbes used as probiotics, but certain yeasts and bacilli may also be used.

Probiotics are commonly consumed as part of fermented foods with specially

added active live cultures, such as in yogurt, soy yogurt, or as dietary

supplements.

2. Sterility Testing

Sterility testing is a critical

quality control process used to ensure that sterile pharmaceutical products

such as injectables, ophthalmic solutions, and surgical implants are completely

free from any viable microorganisms. This test is especially important for

products that are introduced directly into sterile areas of the body, like blood,

eyes, or tissues, where even a single contaminating microbe can cause severe

infection or sepsis. The process involves incubating samples of the product in

specially prepared culture media, such as Fluid Thioglycollate Medium (FTM) and

Soybean-Casein Digest Medium (SCDM), under controlled conditions for at least

14 days to observe microbial growth. For instance, an intravenous infusion must

undergo sterility testing to confirm that it does not contain any bacteria or

fungi before it can be released to the market.

3. Microbial Contamination Control

Microbial

contamination control is essential for non-sterile pharmaceutical products like

tablets, capsules, syrups, creams, and ointments, which may be exposed to the

environment during manufacturing and packaging. This process involves regular

environmental monitoring, personnel hygiene checks, and testing of raw

materials, in-process materials, and finished products. The goal is to prevent

the presence of objectionable microorganisms, such as Escherichia coli, Pseudomonas

aeruginosa, and Salmonella species, which can cause infections or degrade the

product. For example, Pseudomonas aeruginosa in a topical ointment could infect

wounds and delay healing, hence its presence is unacceptable in such

formulations. Microbial contamination control ensures that the microbial

content stays within acceptable limits and does not pose health risks to

patients.

4.

Microbial Limit Testing

Microbial

Limit Testing (MLT) is used to determine the total number of viable aerobic microorganisms—both bacteria and fungi—present in a

non-sterile pharmaceutical product. This test helps assess whether the

microbial count falls within acceptable limits defined by pharmacopeias (like

USP, BP, or IP). MLT consists of two components: Total Aerobic Microbial Count (TAMC) and Total Yeast and Mold Count (TYMC). Additionally, it includes

specific tests to detect pathogenic

organisms, such as E. coli, Salmonella, and Staphylococcus

aureus. For example, a cough syrup might be tested for its total microbial

load to ensure it contains fewer than 100 colony-forming units (CFU) per mL of

bacteria and fewer than 10 CFU/mL of fungi, ensuring it is safe for oral

consumption. MLT is crucial for maintaining the microbial quality of non-sterile products.

5.

Preservative Effectiveness Testing (PET)

Preservative

Effectiveness Testing, also known as antimicrobial preservative effectiveness

testing, is performed to verify that the preservatives added to multi-use pharmaceutical products are

effective enough to prevent microbial growth during storage and usage. This is

especially important in products like eye

drops, nasal sprays, creams, and syrups, which may be repeatedly exposed

to air or come into contact with users. In this test, the product is

intentionally inoculated with known microorganisms (e.g., Staphylococcus

aureus, Candida albicans, Aspergillus brasiliensis) and

observed over time to see whether the preservatives can eliminate or significantly

reduce microbial growth. For instance, in a multi-dose eye drop, PET ensures

that if bacteria are accidentally introduced during usage, they will not

multiply and compromise the product's safety.

6.

Plays a Role in Innovation

Pharmaceutical

microbiology helps in the discovery of new antimicrobial agents and in

developing rapid diagnostic techniques.

It

is important for addressing antibiotic resistance and ensuring the continued

effectiveness of medicines.

Note-

The exploitation of

microorganisms and their products has played an increasingly prominent role in

the diagnosis, treatment and prevention of human diseases. The nonmedical uses

are also of significance, Example, the use of bacterial spores (Bacillus

thuringiensis) and viruses (baculoviruses) to control insect pests, the

fungus Sclerotinia sclerotiorum to kill some common weeds, and

improved varieties of Trichoderma harzianum to protect crops against

fungal infections.

· Diagnosis of diseases and treatment- Different tests are used to

detect infectious microorganisms like ELISA, Widal test. Antimicrobial

Susceptibility testing is mainly used for selection of antibiotics for the

treatment of microbial infections.

·

Apart from drugs and bio

products development, microbiology contributes towards quality control of a

pharmaceutical laboratory. Regular environmental monitoring in manufacturing areas ensures

early detection of contamination sources. Personnel hygiene monitoring ensures that staff do not introduce harmful

microbes into clean areas.

References

- Denyer,

S. P., Hodges, N. A., & Gorman, S. P. (2004). Hugo and Russell's Pharmaceutical

Microbiology (7th ed.). Blackwell Publishing.

- WHO. (2002). Guidelines

on Good Manufacturing Practices for Pharmaceutical Products. World

Health Organization.